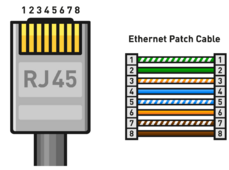

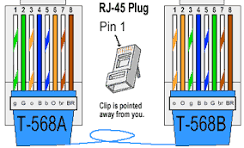

We have already updated the manual to show the necessary pinout of the parallel cable. We will be making this accessible in all our manuals for equipment that have cables to alleviate any sort of confusion. The photo below will be attached to all paralleling guides moving forward.

View attachment 218684

When inverters or other units are sent in for UL Testing/Certification, you have to send in the installation manual. They test the inverter to make sure that it works as advertised when following the specifications of the manual. They test the inverters rigorously, and make sure that the proper error codes are thrown. I don't personally know if they test cross-over cables, but in this case specifically, the paralleling cable was a cross-over cable, and was not what was provided. It's an easy mistake to make, but that is why we will make sure that information is always available moving forward.

I am making all of the information from the previous thread available to our engineering team as well. We will be testing and working to find ways to mitigate any sort problems from using improper communications between inverters so that situations like this no longer arise.

I appreciate the time, effort, and work that went into solving this issue by everyone here in the forum, and the information that

@automatikdonn and

@canadianintruder made available to everyone here in the forum and the EG4 team.