carbondrewtonium

Intentional, tiny, off-grid living

Hi. I’ve researched off and on for about a year. I’m running electric in my tiny home now so I am to the point of gathering up a cohesive system to be off-grid. I bought 7 Qcell 405w panels (I’ve been told 7 is a weird number to have, so I may sell one). I have two 12v Chvrge batteries but in researching, I believe I should get one 48v battery (Probably the EG4 I see so much hype about) and sell the two 12v batteries. I plan on getting two of these ground mounts: https://signaturesolar.com/eg4-brig...ck-kit-4-panel-ground-mount-adjustable-angle/

I’ve been told Victron is the way to go off-grid, but have also read good things about Sunny Islands and Outback inverters.

I have not looked into charge controller much because I don’t know what size inverter I need.

Am I wrong that the larger the battery voltage is, the smaller wattage inverter I’ll need?

I gave this thread the title because I want to emphasize I plan to have very efficient appliances and I am doing without some common appliances.

I’ll have a mini split (Senville 9k BTU, 20.5 SEER), (2) portable single induction cooktops, a Breville toaster oven, microwave, range hood, energy recovery ventilator, projector, ceiling fan, lights, outlets. That’s it. No water heater. No clothes dryer. Maybe a portable clothes washer later on. Oh, and I hope to power tools outside. Miter saw, table saw, etc. Maybe a CNC machine in the future.

I have a 100 amp breaker box, if that matters.

Anywho, if I want to ground mount 6 405w panels, what size inverter and controller should I look into that will give me the power I need?

Any wisdom on size, brands, etc. are welcomed and appreciated.

I’ve been told Victron is the way to go off-grid, but have also read good things about Sunny Islands and Outback inverters.

I have not looked into charge controller much because I don’t know what size inverter I need.

Am I wrong that the larger the battery voltage is, the smaller wattage inverter I’ll need?

I gave this thread the title because I want to emphasize I plan to have very efficient appliances and I am doing without some common appliances.

I’ll have a mini split (Senville 9k BTU, 20.5 SEER), (2) portable single induction cooktops, a Breville toaster oven, microwave, range hood, energy recovery ventilator, projector, ceiling fan, lights, outlets. That’s it. No water heater. No clothes dryer. Maybe a portable clothes washer later on. Oh, and I hope to power tools outside. Miter saw, table saw, etc. Maybe a CNC machine in the future.

I have a 100 amp breaker box, if that matters.

Anywho, if I want to ground mount 6 405w panels, what size inverter and controller should I look into that will give me the power I need?

Any wisdom on size, brands, etc. are welcomed and appreciated.

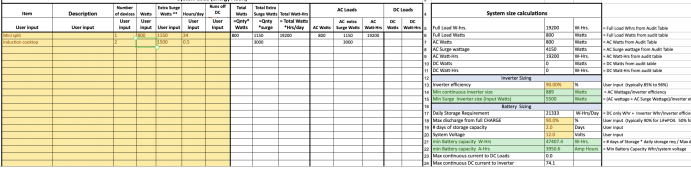

![IMG_0483[1].JPG IMG_0483[1].JPG](https://diysolarforum.com/data/attachments/158/158211-127d93f4ca215102e09c9b286975b699.jpg)

![IMG_0484[2].JPG IMG_0484[2].JPG](https://diysolarforum.com/data/attachments/158/158212-78d89e9fb8db8a6c99e5cff648201cd4.jpg)