ArthurEld

Solar Wizard

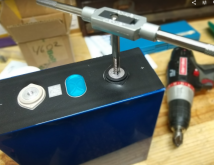

This was supposed to be here-

I just went and did the other one

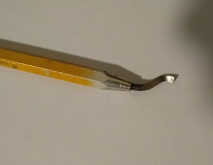

Hole drilled. Ground off drill. Doesn't need to cut in the center. Good thing

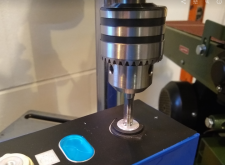

Flat bottom hole

Rotate by hand in drill press to start tap exactly perpendicular

Removed from drill press to finish by hand

Cut off 2 threads

Finished with ugly countersink. I'll do better next time

I'll do better next time

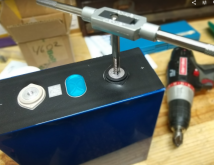

Finished product and tang

I just went and did the other one

Hole drilled. Ground off drill. Doesn't need to cut in the center. Good thing

Flat bottom hole

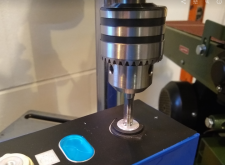

Rotate by hand in drill press to start tap exactly perpendicular

Removed from drill press to finish by hand

Cut off 2 threads

Finished with ugly countersink.

Finished product and tang

Last edited: