wiseacre

Solar Addict

Diverting aluminum from making beer cans to manufacturing wire is against my religion

I prefer glass containers myself...Diverting aluminum from making beer cans to manufacturing wire is against my religion

No need for light bulbs there are some weird conditions where I can sort of see it.

But id like to see it on paper so post that if you can

Only kings with very bad advisers; gold is not even as good as copper for conducting electricity.Gold is for kings, silver is for the peasants.

I think I hit a nerve with your, "I see you speak for the group," I thought we are just play fighting in here. my apology for calling out the logical fallacy; I may have been too blunt (I've been accused of much worse before). No hard feelings ok?I see you speak for the group. However my comment was not a strawman because it was to the point you made later in your post about buying supposedly copper wire (rated as such) only to find it was CCA.

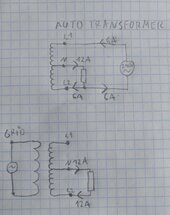

Backfeeding is a weird condition.Here you go. No weird conditions needed, just standard operation of an auto-transformer, including if you backfeed 240V from PV inverter into your split-phase panel, and have unbalanced 120V loads (utility transformer serves as auto-transformer in this case).

Auto-transformer L1/N/L2 current

Transformers aren't well understood by most people who use them. It is well known that centertap "Neutral" connection carries the difference between L1 and L2, but that is not at all true for autotransformers. It is only true for the case of an isolation transformer where all power is delivered...diysolarforum.com

I regularly see grid L1 at -300W and grid L2 at 800W, because I set a 500W grid setpoint with the Victron ESS.Backfeeding is a weird condition.

Or at least was, times have changed.

Backfeeding is a weird condition.

Or at least was, times have changed.

Pretty normal looking

I never seen Polish cable before

Dobry!

Actually I will, because I'm only using strings of ~11A panels, but this particular cable is acceptable for quite a bit more. Constant long term current (3 conductors with current, one without, single cable in soil temp 20C, air temp 30C, allowable cable temp 90C) in soil is 68A (sounds pretty high right?) . How come?Assuming your doing something that looks like normal continental wiring you are going to feed that from 16 amp protection device

I think our cable naming standards are a translation of GOST, but interestingly for technical standards German standards have influenced Poland a lot more.Did GOST ( гост )influence electrical and construction equipment and practices in Poland at one time?

In Canada and Mexico the influence of American standards by NFPA ( fire protection ) directly influences the way we build and wiring things.