Where can I find the build date?Hey all,

I recently got my two 6500ex's from signature solar, the build date on them is 10/2022. I assumed the bonding screws were in place from reading this forum and contacted signature solar for permission to remove them, they gave me permission, and I went ahead and opened them up, and the bonding screws were not there! I wish I knew about this before so I didn't have to open the case.

This is great and how it should be shipped, thank you EG4!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Newer models of EG4 6500ex are built without the bonding screw

- Thread starter vladkgb

- Start date

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

I wonder if it was a conscious choice to ship this way or if they have a quality control problem on the manufacturing line. (I have a suspicion it is a quality control problem)Hey all,

I recently got my two 6500ex's from signature solar, the build date on them is 10/2022. I assumed the bonding screws were in place from reading this forum and contacted signature solar for permission to remove them, they gave me permission, and I went ahead and opened them up, and the bonding screws were not there! I wish I knew about this before so I didn't have to open the case.

This is great and how it should be shipped, thank you EG4!

UPDATE: EG4 has told me they are purposely shipping their units this way. See post #32

Last edited:

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,572

I wonder if this was a previously returned unit.

Where the previous customer had removed the screw.

Where the previous customer had removed the screw.

Quattrohead

Solar Wizard

Yeah it was certified with or without the screw, you can't have it both ways. All certifications are invalid if you change something like this mid-production run or one run to the next. These are the QA issues that you're getting for cheap product.So is it done after the TuV certificate was issued? How about if it is not multiple unit setup why remove it then? How can it passes EMI test without that screw in place?

I wonder, I had worked with UL, TuV, Intertek ETL to get products to pass compliance test, if I remove/change critical component I will be in big trouble when inspector shows up and take the unit from stock for surprised inspection.

I just tested the continuity between ground and neutral for each inverter, there was none. I also finished setting them up today and ran a small load, worked well.

I agree, in some cases this could be dangerous to operate without the NG bond in the inverters. I haven't checked the manual to see if they added the fact that both screws are out. Will do tomorrow.

I agree, in some cases this could be dangerous to operate without the NG bond in the inverters. I haven't checked the manual to see if they added the fact that both screws are out. Will do tomorrow.

The build date was on the sticker that is over the top screw on the right side of the case.Where can I find the build date?

I doubt it because it has an in tact sticker over the screws and it's super clean inside. I would expect some dust around the fans if it was used for any amount of time. There's also two of them.I wonder if this was a previously returned unit.

Where the previous customer had removed the screw.

If this was the case, I would get continuity on ground and neutral right?@vladkgb When you opened that case, did you take it apart far enough to look at the back of the board where the screw is? Are there traces that could still contact the metal that the screw screws into?

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Maybe, maybe not. On the 5000ES, we know the screw holds the trace on the back of the board down against the metal. When the screw is removed, the board can flex away from the metal and break the contact.... or it could also stay touching if the board flexes down. I am trying to find out if the 6500 has this possibility.If this was the case, I would get continuity on ground and neutral right?

Sorry I closed the case up. If I get in there again for whatever reason I can mess with that. But as it is, there's no bond in each of the inverters with those screws gone, so I'm not worried about what you're describing. This is a stationary setup, so there shouldn't be any flex anyway.Maybe, maybe not. On the 5000ES, we know the screw holds the trace on the back of the board down against the metal. When the screw is removed, the board can flex away from the metal and break the contact.... or it could also stay touching if the board flexes down. I am trying to find out if the 6500 has this possibility.

timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,572

There is no trace on the back of the 5000ES board.Maybe, maybe not. On the 5000ES, we know the screw holds the trace on the back of the board down against the metal. When the screw is removed, the board can flex away from the metal and break the contact.... or it could also stay touching if the board flexes down. I am trying to find out if the 6500 has this possibility.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Forgive me. I was not precise enough with my statement.There is no trace on the back of the 5000ES board.

Some of the earlier Growatt 5000ES inverters sold in Europe had traces on the back and that made pulling the screw out an unreliable way to turn off the dynamic bonding. Signature solar had them build a version for the US that did not have this issue. (I do not know if that version is now being sold in Europe or not), Growatt, EG4, and MPP inverters are all designed and built by the same company, so I wanted to see if there is a similar issue with the EG4 6500.

timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 18,572

Still incorrect. None of them had it. It was a false statement made by Signature Solar.Forgive me. I was not precise enough with my statement.

Some of the earlier Growatt 5000ES inverters sold in Europe had traces on the back and that made pulling the screw out an unreliable way to turn off the dynamic bonding. Signature solar had them build a version for the US that did not have this issue. (I do not know if that version is now being sold in Europe or not), Growatt, EG4, and MPP inverters are all designed and built by the same company, so I wanted to see if there is a similar issue with the EG4 6500.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

WOW!!! I had an exchange with EG4 support and they confirmed that they are no longer installing the bonding screw.

This is the message I sent them:

This was their response:

Edit: Clarified the recommendation.

Since they are no longer shipping with the bonding screw and have not said they support a common neutral. I do not recommend using these inverters in *ANY* configuration that uses the AC inputs tied to the grid. Even the simplest single inverter set-up can not be done safely.

This is the message I sent them:

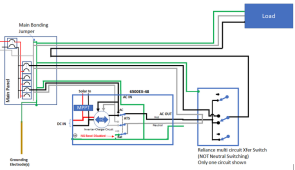

Many people use EG4 inverters with a Reliance multi-circuit transfer switch. This line of transfer switches doesn't switch neutral but is popular for retrofits because it combines the transfer switch and critical load box.

If you trace the output neutral, you will see that it ends up connecting back to the input neutral. In order to avoid multiple NG bonds, this requires the bonding screw be removed in the inverter.

Many people have set the inverter up this way and by all reports, it works fine. However, it is very unclear whether this is supported by EG4.

1) Does EG4 support the removal of the bonding screw? If not, then this configuration and *any* multi-inverter stacking will violate the NEC code around Neutral-ground bonding.

2) Assuming the bonding screw is removed, does EG4 support common neutral layouts such as this.

I have tried to get clear answers to these questions from your distributors but have been unable to. Consequently, I am advising people not to use the EG4 inverter in this configuration or any multi-inverter stacked configuration. If I could get a clear statement from EG4 on these questions I would appreciate it.

Note: As with the situation with the input current, the support (or lack thereof) of these two items needs to be clearly documented in the EG4 documentation. There are significant safety implications and the designers/users need clarification on what is allowable.

This was their response:

Because every installation differs, we want to be able to provide the best possible answer for your question/concern. While the bonding screw is now being removed from all units, we do support the removal of ones that currently have it present as long as documentation is provided by the customer to their distributor that an assessment was made by an installer recommending to do so.

We are currently discussing with our engineering department as to the best way to address this concern from yourself and many other customers, so as soon as we have a more concrete answer, we will be sure to reach out and inform you of any updates we receive.

Thank you for your continued support and patience.

EG4 Electronics Support

Edit: Clarified the recommendation.

Since they are no longer shipping with the bonding screw and have not said they support a common neutral. I do not recommend using these inverters in *ANY* configuration that uses the AC inputs tied to the grid. Even the simplest single inverter set-up can not be done safely.

WOW indeed!WOW!!! I had an exchange with EG4 support and they confirmed that they are no longer installing the bonding screw.

This is the message I sent them:

This was their response:

Since they are no longer shipping with the bonding screw and have not said they support a common neutral. I do not recommend using these inverters in *ANY* configuration. Even the simplest single inverter set-up can not be done safely.

Bud Martin

Solar Wizard

- Joined

- Aug 27, 2020

- Messages

- 4,843

"we do support the removal of ones that currently have it present as long as documentation is provided by the customer to their distributor that an assessment was made by an installer recommending to do so."

I am having a hard time trying to understand what that means.

I would think it will be the manufacturer/seller is the one that provides the documentation to the installer and the customer.

I am having a hard time trying to understand what that means.

I would think it will be the manufacturer/seller is the one that provides the documentation to the installer and the customer.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

In my opinion, they are making the whole problem worse by making changes to this critical part of the product but not addressing how to set the product up safely in all supported configurations."we do support the removal of ones that currently have it present as long as documentation is provided by the customer to their distributor that an assessment was made by an installer recommending to do so."

I am having a hard time trying to understand what that means.

I would think it will be the manufacturer/seller is the one that provides the documentation to the installer and the customer.

Last edited:

BenFromSignatureSolar

Solar Addict

Bonding externally is always best practice. If you look at almost all major brands like SolArk, Schneider, Victron, Outback, there will not be a bond present in the unit. Allowing the end user to ground outside the unit will allow for safely stringing multiple inverters. I'm very confused by the statement that they are now unsafe without the bond. This makes the units safer and gives the possibility of more usage cases. The only time I would personally want a bond present in the unit is if I were running a single unit in an entirely offgrid set up, an RV application, or marine usage.

I do understand the frustration of having older units that had the bond present but now do not. Changing this made the most sense for the users since there are numerous usage cases and not being bonded was most practical for the majority of these. NG Bonding is a topic that can be confusing and frustrating.

I do understand the frustration of having older units that had the bond present but now do not. Changing this made the most sense for the users since there are numerous usage cases and not being bonded was most practical for the majority of these. NG Bonding is a topic that can be confusing and frustrating.

Bud Martin

Solar Wizard

- Joined

- Aug 27, 2020

- Messages

- 4,843

So the ground screw for the PCB (part of the EMI filter circuit, and Etc.) is removed AFTER compliance certificated is issued, if that is the case then it is no longer complied to test that was done to get compliance.Bonding externally is always best practice. If you look at almost all major brands like SolArk, Schneider, Victron, Outback, there will not be a bond present in the unit. Allowing the end user to ground outside the unit will allow for safely stringing multiple inverters. I'm very confused by the statement that they are now unsafe without the bond. This makes the units safer and gives the possibility of more usage cases. The only time I would personally want a bond present in the unit is if I were running a single unit in an entirely offgrid set up, an RV application, or marine usage.

I do understand the frustration of having older units that had the bond present but now do not. Changing this made the most sense for the users since there are numerous usage cases and not being bonded was most practical for the majority of these. NG Bonding is a topic that can be confusing and frustrating.

Did EG4 resubmit the change to the TuV about the change?

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Are you saying it is acceptable to tie the output neutral back to the input neutral of the inverters? That is what schnider and solark *require*. I would need to look up outback, but my bet is they at least allow it and may require it as well. Victron does not require it, but my bet is that they allow it. Furthermore, I can get clear documentation on how these products handle bonding and what is supported.Bonding externally is always best practice. If you look at almost all major brands like SolArk, Schneider, Victron, Outback, there will not be a bond present in the unit. Allowing the end user to ground outside the unit will allow for safely stringing multiple inverters. I'm very confused by the statement that they are now unsafe without the bond. This makes the units safer and gives the possibility of more usage cases. The only time I would personally want a bond present in the unit is if I were running a single unit in an entirely offgrid set up, an RV application, or marine usage.

I do understand the frustration of having older units that had the bond present but now do not. Changing this made the most sense for the users since there are numerous usage cases and not being bonded was most practical for the majority of these. NG Bonding is a topic that can be confusing and frustrating.

In the past I have been told by Signature Solar and others that a common neutral configuration is not a permitted configuration. Without the common neutral configuration and no bonding screw, there is no reasonable way to install these safely if the AC input is hooked up to the grid.

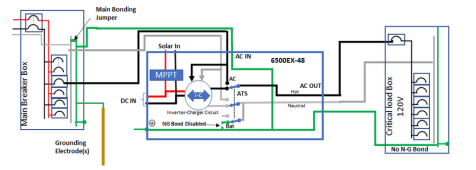

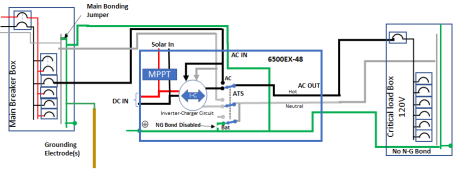

Let's look at this simple setup of one of these inverters without the bonding screw in place:

With this simple setup, there is no NG bond on the output when the inverter is in battery/invert mode. Furthermore, if the installer puts an NG bond in the critical load box, there will be two NG bonds when the inverter is in pass-through mode. Either way, the system is unsafe.

There are only two ways I can think of to make this very simple configuration safe.

- Replace the NG bond screw...But the user does not have the screw and even if they can get the screw it is not clear NG4 supports it.

- Run a neutral connection from the main breaker box neutral bar to the critical load box neutral bar.... But NG4 has not said this is supported and others have said it is not supported.

The same problems exist with the more complex stacked configurations. Without the bonding screws or a common neutral, you can't set them up safely.

BTW: You may want to review this thread as well:

EDITED TITLE: Why not common Neutral? What is dangerous about it?

As many of you know, The value-priced inverter manufacturers provide horrible documentation so I have been on a mission to understand the grounding and bonding of the popular value-priced inverters. Edit: Corrected Ground to Neutral. As part of this, the question of 'common Neutral' has come up...

In that thread, I do a deep dive into this set of issues.

There are *many* aspects of this that are frustrating. Having no way to tell externally if a particular unit shipped with or without the screw is just one of them.I do understand the frustration of having older units that had the bond present but now do not. Changing this made the most sense for the users since there are numerous usage cases and not being bonded was most practical for the majority of these. NG Bonding is a topic that can be confusing and frustrating.

* Changing a fundamental safety characteristic of a product without a broad and detailed communication of the implications.

* No clear documentation of how the inverter handles neutral bonding.

* No clear documentation of what configurations are supported around neutral bonding

* Inconsistent answers to questions about bonding and what is supported.

* Dismissive responses from signature solar that do not answer the questions about bonding and what is supported.

This set of issues was a known problem before EG 4 release their clone. Furthermore, I raised the issues with EG4 as soon as the first inverter was released. The person at EG4 I was working with originally (and is still on this forum) ghosted me after a while. I have also had very unproductive exchanges with signature solar about this.

So yes I am frustrated. The problem is getting worse, not better and because there is no clearly supported way to set them up safely, my recommendation will remain "Do not use".

There are three simple things EG4 can do to change my mind.

1) Support common neutral wiring.

2) Ship *with* the bonding screw and allow the user to remove it without special permission

3) Clearly document #1 and #2 in the manual.

(This is exactly the same as what I asked EG4 to do when the inverter was first released)

You are welcome to PM me if you would like to discuss this privately.

Attachments

Last edited:

Adam De Lay

Solar Wizard

I've always wondered if it would be possible to make this a configuration option in the 6500s. The inverter already programmatically enables/disables the bond depending on whether or not your in grid-bypass or not, so why not expose that configuration ability in the inverter settings? That way depending on each persons unique needs, they can set the bond appropriately. Default it to "on" for each inverter and allow people to turn the bond off no matter which mode the inverter is in.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

I can not say definitely, but I am pretty sure the hardware uses the same signal for the bonding relay as it uses for the transfer switch. If that is the case, the firmware is unable to disable the bonding relay without also disabling the transfer switch.I've always wondered if it would be possible to make this a configuration option in the 6500s. The inverter already programmatically enables/disables the bond depending on whether or not your in grid-bypass or not, so why not expose that configuration ability in the inverter settings? That way depending on each persons unique needs, they can set the bond appropriately. Default it to "on" for each inverter and allow people to turn the bond off no matter which mode the inverter is in.

What you describe, is exactly what Victron does with their systems. If EG4 has any common sense, they would do this on future products. The other thing they should consider is creating a product that does common neutral and no bonding. This product would be the best for the home market but would be difficult to use in the mobile market.

Similar threads

- Replies

- 4

- Views

- 163

- Replies

- 18

- Views

- 701

- Replies

- 36

- Views

- 2K