Previously with my Solar Assistant I had to choose between monitoring my entire hybrid battery (Sealed Lead Acid + LiFePO4) with the Victron Smart shunt or just monitoring the server rack units. I have for a long time just monitored the Victron shunt. However...

I've now finally tried out adding a second instance of Solar Assistant on a spare Raspberry Pi I had. This one is dedicated to monitoring the server rack batteries. I will be adding another all in one inverter/charge controller to it for managing use of my car's vehicle to load for emergency backup charging but that's another story (I actually need it in a few days due to some grid maintenance shut down).

All is working on the second unit:

View attachment 209083

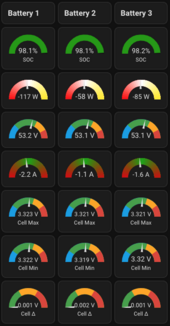

My batteries are server rack units with PACE BMS. Two from Tycorun and one from Jakiper. I already had the Jakiper comms cable, so that made life easier. It connected with and manages the data from the other batteries just fine.

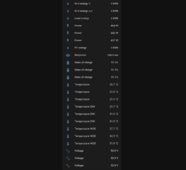

Then I set about getting that data into Home Assistant. That presented a few hurdles I managed to clear and the data is now there as well. Sample:

View attachment 209084

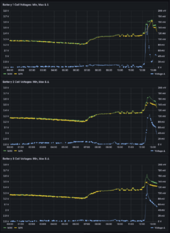

And I have started to create a few charts for tracking a few things, e.g. tracking min, max and cell voltage differentials for each battery:

View attachment 209085

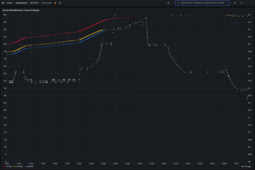

And also tracking the state of charge (SOC) readings from each battery's BMS. This will help me identify when the BMS SOC readings drift and need resetting like they did today.

All it takes is a little voltage pressure at the right time and they reset, like they did today while I performed a supervised rise in charge voltage.

View attachment 209086

Eventually I will learn how the drift in BMS reported state of charge drift behaves and be able to automate having it reset.

All the other data also comes through to Home Assistant, such as internal temperature sensors and cycle counts and is now captured for posterity:

View attachment 209090

View attachment 209091

And since I can now track the whole hybrid battery and the LiFePO4 independently, I will be looking deeper into the behaviour of the batteries as they operate in parallel. That's for a different thread on the operation of hybrid batteries. Things like how is power/current shared, and how/when does the lead acid contribute, charging behaviour, etc.

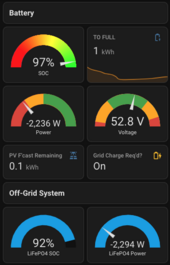

For instance, right at the instant I took this screen shot:

View attachment 209092

The hybrid battery was discharging at 2,236 W while the LiFePO4 is discharging at 2,294 W. How can that be, where is the 58 W going?

While most of the power is going to service loads, a little of the LiFePO4 discharge power is going into the lead acid battery - keeping a little float charge going. 58 W at 52.8 V is 1.1 A. That's not a lot of float charge into 400 Ah of lead acid.

Similarly, when the LiFePO4 state of charge gets low, then the situation reverses and the lead acid begins to contribute.

So I'm going to be able to document this and post some results.