Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,695

A while back I bragged about creative use of heater hose as tough, large size insulation for electrical terminals:

diysolarforum.com

diysolarforum.com

It seemed like a good idea at the time.

More recently, I was wiring up transformers to make 277/480Y out of 120/208Y. Here, most connections are nicely done with set-screw terminal blocks in a box, and a 4-wire plus ground outlet. (for now, I'm using a plug-in cord for Sunny TriPower so things are easy to swap and move around.)

A few loose wires are capped with set-screw wire nuts, and some pairs are joined with split-bolts. Need to get all those inside a box, the one above may or may not fit them. The split bolts (one in background for example) I slipped inside my heater-hose insulation and secured with electrical tape. All good, right??

Well, a bit of smoke and smell of burning rubber appeared. Bad connection getting hot?

I switched things off, tugged to make sure all secure, turned back on and conducted my tests without problems.

Later it happened again.

Finally, a light bulb went off. Why don't I check voltage to the rubber insulation, make sure it really insulates?

328V between two rubber parts!

Good thing I didn't touch them with power on. Wonder how much current it could have delivered?

0.120A, when pulled to zero volts!

Yikes! That thing is a human-safety hazard.

How much power?

328V x 0.120A = 38.4W, no wonder it smoked almost immediately.

328V / 0.120A = 2667 ohms. Not much of an insulator, now is it? (Maybe they meant to do that. Avoid built-up of electric charge due to water flow? Bonding for some corrosion reason?

These were new heater hose, so never had a chance to absorb water or anything else.

I still think the recycled hose is good as robust covers over battery terminals, will prevent a high-current short. But not good to prevent discharge due to contact with a conductive material. My battery has corrugated PVC over the top.

Now I need to get more proper UL listed terminals for my experiment.

I'm just using these toroids temporarily as 120V to 277V (really only getting 260V) auto-transformer.

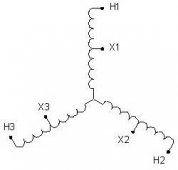

I'm in the market for several 10kVA 240/480 to 120/240 isolation transformers. I'll use three to convert 120V to 480V, and one more between middle of one 480V leg and one corner to establish Neutral.

Fire!! Never cover LiFePO4 with wood!!!

Where did you come up with the "plan" (not sure what to call it) for the 3D printer? It's just a 3D model saved in the correct format.

It seemed like a good idea at the time.

More recently, I was wiring up transformers to make 277/480Y out of 120/208Y. Here, most connections are nicely done with set-screw terminal blocks in a box, and a 4-wire plus ground outlet. (for now, I'm using a plug-in cord for Sunny TriPower so things are easy to swap and move around.)

A few loose wires are capped with set-screw wire nuts, and some pairs are joined with split-bolts. Need to get all those inside a box, the one above may or may not fit them. The split bolts (one in background for example) I slipped inside my heater-hose insulation and secured with electrical tape. All good, right??

Well, a bit of smoke and smell of burning rubber appeared. Bad connection getting hot?

I switched things off, tugged to make sure all secure, turned back on and conducted my tests without problems.

Later it happened again.

Finally, a light bulb went off. Why don't I check voltage to the rubber insulation, make sure it really insulates?

328V between two rubber parts!

Good thing I didn't touch them with power on. Wonder how much current it could have delivered?

0.120A, when pulled to zero volts!

Yikes! That thing is a human-safety hazard.

How much power?

328V x 0.120A = 38.4W, no wonder it smoked almost immediately.

328V / 0.120A = 2667 ohms. Not much of an insulator, now is it? (Maybe they meant to do that. Avoid built-up of electric charge due to water flow? Bonding for some corrosion reason?

These were new heater hose, so never had a chance to absorb water or anything else.

I still think the recycled hose is good as robust covers over battery terminals, will prevent a high-current short. But not good to prevent discharge due to contact with a conductive material. My battery has corrugated PVC over the top.

Now I need to get more proper UL listed terminals for my experiment.

I'm just using these toroids temporarily as 120V to 277V (really only getting 260V) auto-transformer.

I'm in the market for several 10kVA 240/480 to 120/240 isolation transformers. I'll use three to convert 120V to 480V, and one more between middle of one 480V leg and one corner to establish Neutral.

Last edited: