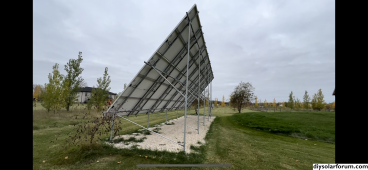

Literally read my mind! Simple but effective! What did you use for the strut? Only concern I have is being told not to loop the wires since it's DC current.I guess I'm far enough along in my build that I can start posting some pics of my ground mount. Here is 12 bifacials on a pergola that I extended to cover my whole deck:

View attachment 173019

View attachment 173020

View attachment 173021

I have an 18Kpv and 6 lifepower batteries. I'm still waiting on my electrician to wire up the 200a disconnect between the inverter and the meter. Currently the 18kpv is connected to a subpanel that powers my hot tub, CNC and the kitchen double oven.

CLEAN!!!