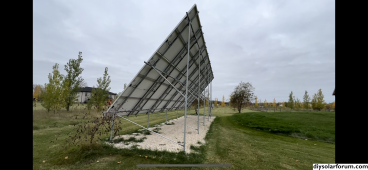

Have begun our Frankenstein semi-ground mount tracking 3.6kw offgrid array to charge our Ford Lightning, and a 10kw battery bank, and power a Garage Mini-split to be named later... It will all be providing shade to a 3-4 bed, raised bed salad garden with rain-barrel fed, and arduino controlled automatic drip irrigation and single axis tracking, and an anemometer for storm/wind orientation. The system will travel around 30 degrees each way and should increase average solar hours by about 2.5 hours. Jury is out as to how long it takes to repay the tracking system, but we will be tracking the tracking...

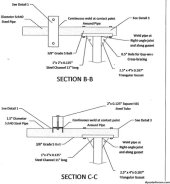

It mounts on swivels from the eco-worthy ground mount kit, of which we have two kits, on one end and we're using concrete 4x4 footing blocks and linear actuators for the other end. Still in early testing stage.

Possibly working with Progressive Automations for hall sensor linear actuators so we have positional control of the actuators. We'll see if they want to partner. Using cheap Vevor test units right now, which are working fine. They are a little sketchy, so they are in process of being replaced this weekend with Eco-Worthy actuators, which are much higher quality, for not much more $$$. Just got the 18" Ecoworthy for $39/per on a $10 off sale. The Eco-worthy actuators arrived two weeks earlier than amazon said they would !

It's all about doing it as cheaply as possible, with as quick of system payback through charging the Lightning. Going for 3-4 year payback. It looks doable with used panels from Santan Solar, and a refurbished EG4 6000ex hybrid inverter, and 4x 12v 200ah powerqueen batteries, but may go up to 6 to 8x batteries. Right now, we're at around $4.5k.

I'll be posting a thread in the show and tell section for this project. First two panels are up. Eventually, we may delve into some machine learning with the agrivoltaic side of the project, varying output/orientation to temperature/soil moisture. Picture 8 more panels going down the fence.