This would be to run the pump for about 15 minutes at most 3 times a day. The pump is AC "230" volts (240V) with a running amps of 10 and a startup surge of 40.17 amps. Measured with a TRMS clamp. Total well depth = 181'Pump depth = 140'Water table = 79' Pump output 20 gpm.

Hi Hedges, thanks for the feedback. Electrical is my weak area. Are you saying that I would require a 48V battery? And a 20,000 watt inverter?

24V should be sufficient, but 48V has much equipment available and would support other things.

If only for water, look at Sunshine's suggestion and see if inverter can be switched when needed.

I like Sunny Island, of course. Available on eBay used or new, $1200 to $2500. But would require a transformer for 240V. Look for a brand with native 120/240V.

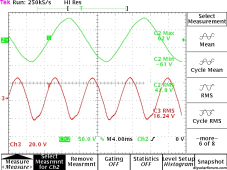

The inverter needs to supply 240V x 10A = 2400W continuous, 240V x 40.17A = 9640W surge for a couple seconds. (30 milliseconds or 100 milliseconds won't cut it; that's only enough to fast-trip a breaker typically more than 5x breaker rating.)

Lots of low frequency inverters, and some high frequency, will supply a few seconds surge 200% of rating. So 5kW inverters would probably do it, including SMA, Schneider, other heavy ones with LF transformer. Some high frequency ones surge well too. Any HF inverter (legitimately) rated 10kW should also work.

2400W/12V = 200A, doable. 2400W/24V = 100A, reasonable. 2400W/48V = 50A, easy.

Starting surge 800A @ 12V, possible. 400A @ 24V, doable. 200A @ 48V, reasonable.

Lead-acid could do any of those; the starting batteries in my truck are good for 800A and there are two in parallel. My home system has 48V 405Ah, 24kW of inverters, 44kW surge (not that I've tried, would be 900A 2.25C)

45 minutes/day at 20 gallons/minute. 900 gallons/day. The volume is reasonable.

It would be better if you could pump 6 hours continuous per day or more drawing only 300W. 180' is 90 PSI. Small positive displacement pump? Is a lower wattage deep well pump available that can do the head? I don't know what the options are.

People us MicroAir Easy-start for air conditioners. That requires access to starting windings. Is your pump 3-wire or 2 wire? It is also possible that slow-starting a deep well pump wears it out faster - somebody said bearings ride on film of water.