Alkaline

Solar Wizard

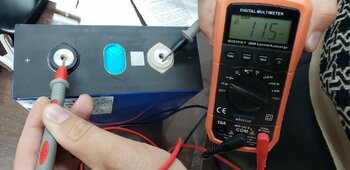

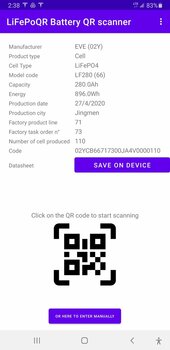

Well in the back of my mind I knew it was only a matter of time, and now in less than 3 years the basen 280 EVE "Grade A" is dead. Checked the voltage and its 0 volts (or 0.012 v). Purchased from Alex Chen in Feb 2021...

This was in a 8s battery back with an overkill solar BMS, the other cells were at 3.34 volts so this one just died. Its also swollen beyond recognition. I made 3 of these 8s packs 1 with xuba cells, with 1 basen, and the other with Luyuan. The luyuan is the only one that is performing properly. All 3 battery packs were sold to a local guy who uses it in his camp and has maybe 100 or so cycles on them. I told him upfront they were probably grade b except for the Luyuan and he said he understood.

So now... anyone have an old 280DK cell they need to get rid off?

JUNK.

This was in a 8s battery back with an overkill solar BMS, the other cells were at 3.34 volts so this one just died. Its also swollen beyond recognition. I made 3 of these 8s packs 1 with xuba cells, with 1 basen, and the other with Luyuan. The luyuan is the only one that is performing properly. All 3 battery packs were sold to a local guy who uses it in his camp and has maybe 100 or so cycles on them. I told him upfront they were probably grade b except for the Luyuan and he said he understood.

So now... anyone have an old 280DK cell they need to get rid off?

JUNK.

Attachments

Last edited: