Westking is renowned as a 150VDC HSF21J High Speed Fuse professional manufacturer and supplier in China, specializing in providing high quality 150VDC HSF21J High Speed Fuse to meet your requirements. Additionally, we offer competitive pricing for customized 150VDC HSF21J High Speed Fuse. By...

www.westking-fuse.com

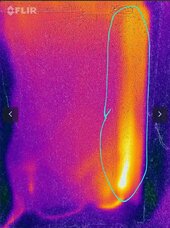

The specifications look pretty good to me. Does not imply quality, but I don’t think the fuse is to blame.

I like how they call themselves “renowned”

#1 washers, #2 fuse holder

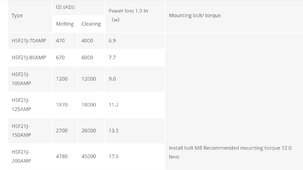

There is a torque specification!

Also, the fuse will put out 17.6W of heat at 200A.

View attachment 221219