I think part of the confusion is my fault for not communication how I'm accepting feedback.

I'm reading opinions in two different ways.

The first way, the most important way, is accepting critiques and suggested ways to improve. This might not be obvious but I have read everyone's opinion and acted on it.

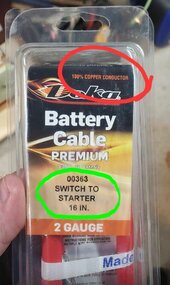

Quality cables of the correct gauge. Check.

Correct torque. Check.

Noalox. Check.

No steel in the path of conduction. Check.

UL listed class T fuses. On their way.

If I've missed anything please let me know.

Maybe I haven't done a good enough job expressing gratitude to everyone contributing on their excellent input. So thanks everyone, great input.

The second way is just curiosity as to what exactly happened. And here I think is where the friction is coming from. Just because I'm unconvinced that a weakness in my methods caused this event doesn't mean I don't agree that it's a potential problem worth correcting.

So, everyone who is talking to me in all caps, I hear you, I see you. Your feedback is not lost on me.

And finally, who wants to see the inside of a class t fuse?

View attachment 222581

Here it is with the case cut open. That ceramic layer was a bitch.

Here it is with the sand blown out.

View attachment 222582

An interesting design. 4 fuse elements with strain relief encased in sand inside a ceramic chamber protected by... brass? aluminum?