You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do my new blue cells need to be packed together ?

- Thread starter Aussiecroc

- Start date

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Interesting. I really like the big posts they use on all their batteries.The 100Ah "fortune" cells actually come from Jiangsu Frey.

https://frey.en.alibaba.com/product....icbuShop.41413.42.e4d718ccxIFmSc&filter=null

Interesting. I really like the big posts they use on all their batteries.

https://frey.en.alibaba.com/product....icbuShop.41413.42.e4d718ccxIFmSc&filter=null

Yeah, they are nice and beefy. I can't imagine dealing with some of the sketchy connections I see offered on some other cells.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

I sent a message to Jiangsu Frey for pricing on their 8 cell packs.

https://frey.en.alibaba.com/product...h_lifepo4_battery_rechargeable_batteries.html

I asked price and shipping for 1 pack and 10 packs (possible group buy).

https://frey.en.alibaba.com/product...h_lifepo4_battery_rechargeable_batteries.html

I asked price and shipping for 1 pack and 10 packs (possible group buy).

John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,233

I sent a message to Jiangsu Frey for pricing on their 8 cell packs.

https://frey.en.alibaba.com/product...h_lifepo4_battery_rechargeable_batteries.html

I asked price and shipping for 1 pack and 10 packs (possible group buy).

How many in a pack?

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

I asked that too..... but I assume it is 8.

I would for sure be interested in the 200ah version if they have the big posts and the cool tops and bottoms on them. I'm thinking about trying to 3d print those for the 280ah cells in some other posts.I sent a message to Jiangsu Frey for pricing on their 8 cell packs.

https://frey.en.alibaba.com/product...h_lifepo4_battery_rechargeable_batteries.html

I asked price and shipping for 1 pack and 10 packs (possible group buy).

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

yup. It looks like 100AH is the largest cell they make.

Last edited:

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

I also asked for pricing (with shipping) of 8 and 80 of the individual cells with spacers.

https://frey.en.alibaba.com/product...Llifepo4_Cell_Laminated_Battery_36130290.html

https://frey.en.alibaba.com/product...Llifepo4_Cell_Laminated_Battery_36130290.html

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

This is what I got back from Frey for pricing on individual 100AH cells:

Hello Paul,

This is Maggie,glad to get your inquiry.

offer is as following.

for 8pcs, unit price $107.25 ,(FedEX with DDP service,shipping time 8~12days)

for 80pcs,unit price $86.96,(FedEX with DDP service,shipping time 8~12days)

Unit price $77.18,(ocean shipping with DDP service,shipping time 25~30days)

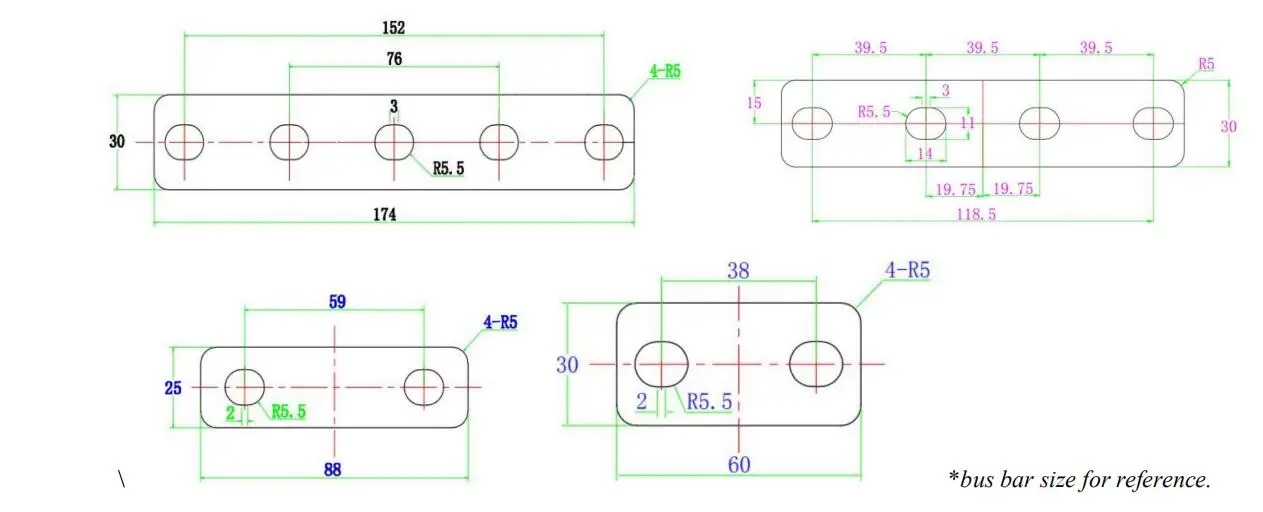

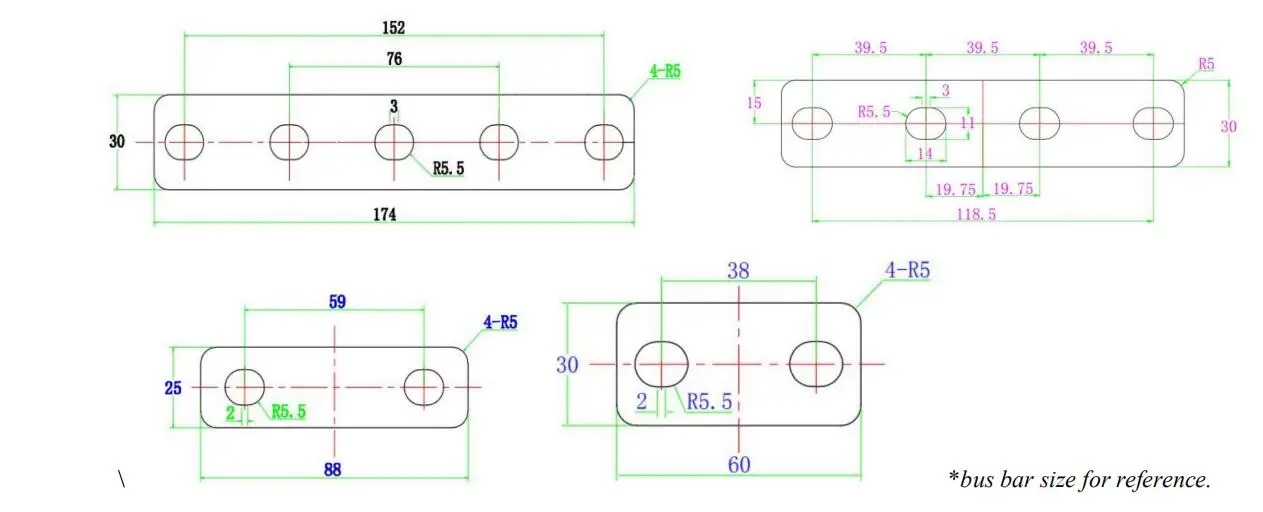

if you need,we also provide bus bar for cells connection as fowlloing;

here's the real product for reference.

Hello Paul,

This is Maggie,glad to get your inquiry.

offer is as following.

for 8pcs, unit price $107.25 ,(FedEX with DDP service,shipping time 8~12days)

for 80pcs,unit price $86.96,(FedEX with DDP service,shipping time 8~12days)

Unit price $77.18,(ocean shipping with DDP service,shipping time 25~30days)

if you need,we also provide bus bar for cells connection as fowlloing;

here's the real product for reference.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

The low volume pricing is not low enough to be very interesting.

mrdavvv

Solar Enthusiast

- Joined

- Jan 14, 2020

- Messages

- 404

Totally agree .. unless you are running 1C or higher then airflow and circulation is minimal concern .. heck at 2C as long as you have the ability to get heat to escape you are fine .. we don't use fans at all until we are talking LARGE systems and high C ratings .. anyone that has to strap cells together to keep them from bulging is totally screwed anyway ... the cells are still DESTROYED - all you have done is kept them from bulging ...

The guy from Nordkyn design says this:

Mechanical Installation

It was once thought prismatic cells could be operated in more or less any position as they do not really contain free liquid. Nowadays manufacturers are a lot more prescriptive with installation position. In most instances, the only acceptable position is upright, vent cap and terminals on top (Sinopoly, Winston). Sometimes it may be acceptable to mount them on edge, with the terminals on the side (CALB). This may vary not only between manufacturers, but also between cell models, so seeking specific guidance is a sensible step if an odd installation position is being considered.

When questioned, Sinopoly indicated that installing the cell in any other position than upright would cause some of the plates to run dry after a while, damaging it. Installing them flat on their side is out of the question in all cases.

The cells must be installed securely in such a way that no movement is possible in relation with each other, or it will stress the terminals and link plates. Prismatic cells should also be clamped together between compression plates as the application of a modest amount of pressure helps with preventing electrode delamination, even more so in the presence of shocks and vibrations as found on marine vessels. It also helps with preventing the internals of the cells from shifting in case of violent shock, which can lead to internal cell short-circuits. Clamping is a common warranty condition from manufacturers. Strapping the cells together is simply not good enough for that matter.

The bank must also be installed in such a way that it can’t shift and nothing can come and short-circuit the cell terminals. This can involve fitting a cover over the cells.

So he talks about avoiding electrode delamination by adding pressure. I recall watching a BYD dissasembly video and indeed they are tighly packed together (Altough they are designed for high C rates).

Considering all of this since if this is an issue in our systems my mounting design its terribile for lifepo4:

Checkout my design! - Vertical mounting of prismatic LIFEPO4

So my 16 x 280AH Lifepo4 cells finally arrived. Now its the time to start building the battery pack's! 24V System for an hybrid inverter LV2424 2 x Battery Pack with 8 Cell each one, connected in series. Daly 200A BMS for each pack. 100A Fuse for each pack. Both packs connected in parallel with...

- Mounting the cells by their side

- Not straping the cells together and adding pressure.

ghostwriter66

"Here - Hold my Beer"

The guy from Nordkyn design says this:

So he talks about avoiding electrode delamination by adding pressure. I recall watching a BYD dissasembly video and indeed they are tighly packed together (Altough they are designed for high C rates).

Considering all of this since if this is an issue in our systems my mounting design its terribile for lifepo4:

Checkout my design! - Vertical mounting of prismatic LIFEPO4

So my 16 x 280AH Lifepo4 cells finally arrived. Now its the time to start building the battery pack's! 24V System for an hybrid inverter LV2424 2 x Battery Pack with 8 Cell each one, connected in series. Daly 200A BMS for each pack. 100A Fuse for each pack. Both packs connected in parallel with...diysolarforum.com

- Mounting the cells by their side

- Not straping the cells together and adding pressure.

Heat is the #1 killer of batteries -- by far ... I think in the long run that a battery would be better off with a 1/4 or 1/8 spacer between batteries in order to help get the heat up and away then strapping/compressing them in order to help them withstand a huge discharge or charge load .. i think the heat issue is more going to happen then the charge issue ...

Nordkyn's designer writes lots of stuff. Not all of it is accurate, but it all sounds like it is.

The reality is that humanity has learned a lot more about these batteries since someone came up with some ideas ten years ago and started printing them on datasheets. Manufacturing techniques have improved, and we have learned to avoid doing some of the horrible things that semi-justified some of the mitigating measures that were important in yesteryear. We have learned that ESS operating regimes impose different burdens (and lifecycle opportunities) on these chemistries.

Teasing apart which of the ancient rites of battery management are meaningful today, and which are best left discarded on the side of the road, is part of the fun/challenge of DIY batteries today.

For starters, I do not recommend strapping any modern metal-shell battery that will run at sub-C rates. No matter how impressive the blog posts are!

The reality is that humanity has learned a lot more about these batteries since someone came up with some ideas ten years ago and started printing them on datasheets. Manufacturing techniques have improved, and we have learned to avoid doing some of the horrible things that semi-justified some of the mitigating measures that were important in yesteryear. We have learned that ESS operating regimes impose different burdens (and lifecycle opportunities) on these chemistries.

Teasing apart which of the ancient rites of battery management are meaningful today, and which are best left discarded on the side of the road, is part of the fun/challenge of DIY batteries today.

For starters, I do not recommend strapping any modern metal-shell battery that will run at sub-C rates. No matter how impressive the blog posts are!

John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,233

So clamping and strapping are different, and "Clamping is a common warranty condition from manufacturers.".

The quoted bit should be easy to verify.

Is clamping further defined anywhere?

Does a snug fitting plywood box(which leaves the top unclamped) suffice?

I'm thinking of a tube of toothpaste.

The quoted bit should be easy to verify.

Is clamping further defined anywhere?

Does a snug fitting plywood box(which leaves the top unclamped) suffice?

I'm thinking of a tube of toothpaste.

ghostwriter66

"Here - Hold my Beer"

So clamping and strapping are different, and "Clamping is a common warranty condition from manufacturers.".

The quoted bit should be easy to verify.

Is clamping further defined anywhere?

Does a snug fitting plywood box(which leaves the top unclamped) suffice?

I'm thinking of a tube of toothpaste.

So from what i have seen and read - clamping involves a much higher PSI (or whatever its measured in) then just a "snug" box ....There are some LFPs that are designed to actually need to be clamped but the only time I have sen those was in UPS's of some sort ... For what most of us do i think that HEAT dissipation should be a considered first before the cells expanding and collapsing ... I will tell you that if you have a prismatic or a blue aluminum cell expand/swell to a point where you need to be clamping/strapping it to keep it from deforming you are well past the safe use of that cell and no matter how much clamping you have done - that cell is pretty well shot ... anyway thats just my viewpoint -- I see very very little swelling in any of my cells - but i have seen cells go bad by heat .... BUT again it does take allot of heat - I mean like 160F type of continuous heat ...

Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

I AM TOSSING THIS OUT HERE:

Seriously HEAT ? are we talking about DC Fast Charging and pushing an EV down the road ? NO !

WHEN have you seen HEAT issues with LFP packs ?

It takes a lot of amps in/out to make the Cells heat up. This whole preoccupation on the cells heating is a bit much really. Has ANYONE caused their LFP's to reach or exceed the normal specs ? Possibly MAYBE in the most extreme of situations. This isn't like Freeze Protection which is another beast altogether.

Typical Temps for LFP

Charging Temperature 0℃~55℃ (32F ~ 131F)

Discharging Temperature -20℃~55℃ (-4F ~ 131F)

Storage Temperature One month -20℃~45℃ (-4F ~ 113F). One year 0℃~35℃ (32F ~ 95F)

Seriously HEAT ? are we talking about DC Fast Charging and pushing an EV down the road ? NO !

WHEN have you seen HEAT issues with LFP packs ?

It takes a lot of amps in/out to make the Cells heat up. This whole preoccupation on the cells heating is a bit much really. Has ANYONE caused their LFP's to reach or exceed the normal specs ? Possibly MAYBE in the most extreme of situations. This isn't like Freeze Protection which is another beast altogether.

Typical Temps for LFP

Charging Temperature 0℃~55℃ (32F ~ 131F)

Discharging Temperature -20℃~55℃ (-4F ~ 131F)

Storage Temperature One month -20℃~45℃ (-4F ~ 113F). One year 0℃~35℃ (32F ~ 95F)

John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,233

So not that common and basically a tempest in a teacup.<snip> ....There are some LFPs that are designed to actually need to be clamped but the only time I have sen those was in UPS's of some sort<snip>

Spacing it is.

Similar threads

- Replies

- 22

- Views

- 1K

- Replies

- 8

- Views

- 1K

- Replies

- 44

- Views

- 3K

- Replies

- 9

- Views

- 806

- Replies

- 6

- Views

- 737