FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Another nice video from Mike Holt.

Auxilary grounding rods are not required but there is a rule that states there are no requirements on an auxiliary ground e;ectrodes. At one point in the video, he talks about CAT 5 wires and 10 penny nails for the auxiliary grounding electrode.

It has taken several years but we are starting to see both professionals and DIYrs wake up to the fact that auxiliary grounding electrodes are 1) not required and 2) not recommended.

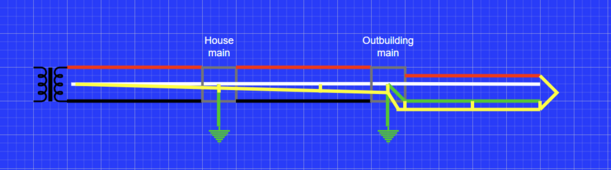

Having said that, I am still a little uncomfortable with the code requirement for a second (not auxiliary) grounding electrode for separate buildings. I would love to see the rationale for this as well as a multi-year study of a bunch of instances where this is not done. The good news is that with just a little planning the 2nd electrode can be set up with the path to the first electrode only going through breaker boxes....but even breaker boxes are starting to get a lot of electronics in them.

Auxilary grounding rods are not required but there is a rule that states there are no requirements on an auxiliary ground e;ectrodes. At one point in the video, he talks about CAT 5 wires and 10 penny nails for the auxiliary grounding electrode.

It has taken several years but we are starting to see both professionals and DIYrs wake up to the fact that auxiliary grounding electrodes are 1) not required and 2) not recommended.

Having said that, I am still a little uncomfortable with the code requirement for a second (not auxiliary) grounding electrode for separate buildings. I would love to see the rationale for this as well as a multi-year study of a bunch of instances where this is not done. The good news is that with just a little planning the 2nd electrode can be set up with the path to the first electrode only going through breaker boxes....but even breaker boxes are starting to get a lot of electronics in them.