ArthurEld

Solar Wizard

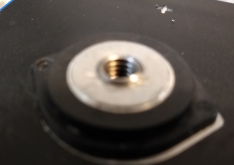

I've been really annoyed about my terminal threads getting messed up.

And I was thinking "Why is this happening now? It didn't happen before"

I think it is from cells expanding and moving around with the tight busbars.

It could also be from torqueing or loosening my fixture with tight busbars. I am going to have to be more conscious of cells moving while busbars are tight.

I bet if I had used regular nuts and washers instead of serrated flanged nuts I wouldn't have this problem. ?

And I was thinking "Why is this happening now? It didn't happen before"

I think it is from cells expanding and moving around with the tight busbars.

It could also be from torqueing or loosening my fixture with tight busbars. I am going to have to be more conscious of cells moving while busbars are tight.

I bet if I had used regular nuts and washers instead of serrated flanged nuts I wouldn't have this problem. ?

Last edited: