Bought 8 LiFePO4 cells, supposedly 105 Ah from "Liitokala Battery Flagship Store". A Facebook solar group I follow had plenty "success stories" with that store so I placed the order.

The cells arrived. Two of them were a bit swollen, but not much. I tried to dismiss the fact, but contacted the seller anyway. Posted pictures of swollen batteries on the chat would not show up because of "inappropriate content". Sharing the pictures via Google Drive but seller said the access is denied even though I made the folder public. I ended up equalizing the batteries by connecting them in parallel, compressed, and attaching them to a benchtop power supply. All were holding the charge at 3.35 V, even the slightly swollen cells did seem to come back to shape.

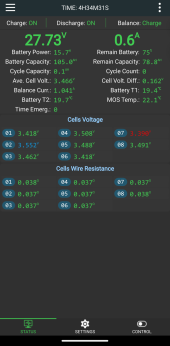

The 24 V battery seemed all right, I hooked it up to the AIO EAsun/Powland inverter and started charging: charging voltage 27.6 V, float at 27.5 V and suddenly bam! Overvoltage protection. The overvoltage protection was set at 3.6V and one cell has reached it while the other cells were not even at 3.3V.

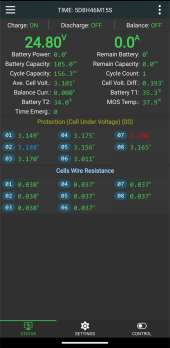

I tried to change the cell position but the issue would follow the cell. A second cell was off as well but not to this extent. Tried to cycle the cells completely, but while other cells were at 3.1xx V this cell would trigger the undervoltage protection at 2.6 V.

I tried to message the seller, they would not answer. Posted a follow-up review, nothing happened. I noticed my review was the only one standing, everything that was posted before,.good or bad was just gone.

So here I am, having a battery I can't use. I tried everything: - to have the inverter disconnect at maximum allowable voltage which is 24 V, that is 3 V per cell: no go, because at 25.1x V the bad cell is already at 2.6 V

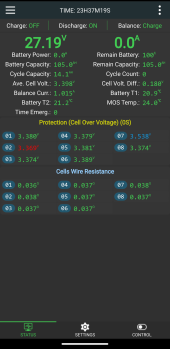

- limit charging to 3.4 V per cell: would get overvoltage protection and get the BMS to pull the plug way early. I had to set it to 3.35 V per cell.

After reading almost everything Liitokala related on this forum I have to say that I've been duped: not only was I sent lower capacity cells (I knew they were not 105 Ah but rather 75-90-ish), but have been sent a 55-60 Ah cell, a 68-70 Ah cell and 6 "good" cells. How did I came to these numbers? Reset the cycle counter on the BMS, and used a A/C unit to pull 58-60 Ah from the battery. Got about 68 Ah Cycle capacity before the AC switched off due to Undervoltage protection.

I'm now facing a dilemma: scrap the somewhat good cells (I can probably build a nice 12 V battery for my father's off grid shed) and call it a loss, or buy a set of 4 cells and hopefully harvest 2 good cells to replace the faulty ones but give some more money to these crooks?

For the $390 I paid them I could have gotten two honest 100 Ah gel cells or I could have saved for 8 Elirix 100 Ah cells.

The cells arrived. Two of them were a bit swollen, but not much. I tried to dismiss the fact, but contacted the seller anyway. Posted pictures of swollen batteries on the chat would not show up because of "inappropriate content". Sharing the pictures via Google Drive but seller said the access is denied even though I made the folder public. I ended up equalizing the batteries by connecting them in parallel, compressed, and attaching them to a benchtop power supply. All were holding the charge at 3.35 V, even the slightly swollen cells did seem to come back to shape.

The 24 V battery seemed all right, I hooked it up to the AIO EAsun/Powland inverter and started charging: charging voltage 27.6 V, float at 27.5 V and suddenly bam! Overvoltage protection. The overvoltage protection was set at 3.6V and one cell has reached it while the other cells were not even at 3.3V.

I tried to change the cell position but the issue would follow the cell. A second cell was off as well but not to this extent. Tried to cycle the cells completely, but while other cells were at 3.1xx V this cell would trigger the undervoltage protection at 2.6 V.

I tried to message the seller, they would not answer. Posted a follow-up review, nothing happened. I noticed my review was the only one standing, everything that was posted before,.good or bad was just gone.

So here I am, having a battery I can't use. I tried everything: - to have the inverter disconnect at maximum allowable voltage which is 24 V, that is 3 V per cell: no go, because at 25.1x V the bad cell is already at 2.6 V

- limit charging to 3.4 V per cell: would get overvoltage protection and get the BMS to pull the plug way early. I had to set it to 3.35 V per cell.

After reading almost everything Liitokala related on this forum I have to say that I've been duped: not only was I sent lower capacity cells (I knew they were not 105 Ah but rather 75-90-ish), but have been sent a 55-60 Ah cell, a 68-70 Ah cell and 6 "good" cells. How did I came to these numbers? Reset the cycle counter on the BMS, and used a A/C unit to pull 58-60 Ah from the battery. Got about 68 Ah Cycle capacity before the AC switched off due to Undervoltage protection.

I'm now facing a dilemma: scrap the somewhat good cells (I can probably build a nice 12 V battery for my father's off grid shed) and call it a loss, or buy a set of 4 cells and hopefully harvest 2 good cells to replace the faulty ones but give some more money to these crooks?

For the $390 I paid them I could have gotten two honest 100 Ah gel cells or I could have saved for 8 Elirix 100 Ah cells.