Bluedog225

Texas

- Joined

- Nov 18, 2019

- Messages

- 2,917

I’ll admit I haven’t been paying attention to the prices of steel lately. But I hear they’re through the roof.

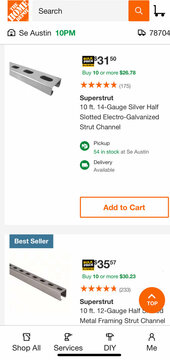

35 bucks a 10 foot stick of unistrut seems crazy.

Normally I buy my stuff off craigslist, but everything seems to have dried up.

I need some horizontal stuff to mount my panels. I don’t really care whether it’s strut or solar mounting rail, or heck, I might even go with treated wood.

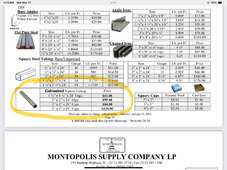

But, I wanted to check with you guys to see if you had some cheaper alternatives that were metal.

Here is what I have so far.

Many thanks.

35 bucks a 10 foot stick of unistrut seems crazy.

Normally I buy my stuff off craigslist, but everything seems to have dried up.

I need some horizontal stuff to mount my panels. I don’t really care whether it’s strut or solar mounting rail, or heck, I might even go with treated wood.

But, I wanted to check with you guys to see if you had some cheaper alternatives that were metal.

Here is what I have so far.

Many thanks.