How do you work that out? I have class T on one of mine. It's the larger fuse as I am fused at 225A. The NH fuse holder is shorter and more compact. I have one of these mounted on my other battery. Much prefer the NH fuseMounting NH fuses is even worse.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dead short fuse trip experiment using an MRBF fuse

- Thread starter Johan

- Start date

I guess it depends on what hardware you use but for example Blue Sea holder is 178mm in total lenghtHow do you work that out? I have class T on one of mine. It's the larger fuse as I am fused at 225A. The NH fuse holder is shorter and more compact. I have one of these mounted on my other battery. Much prefer the NH fuse

And NH1 fuse holder is 250mm long:

More extreme example: something like http://www.vte-europe.com/content/electromech/fuse/html/classt/classt.php

Up to 400A and only 45mm between centers on lug studs, whereas 400A rated NH2 fuse holder is 175mm between lug studs.

To a certain extent I believe the BMS will work. The inadequate (underrated) MEGA fuse is the secondary stop.Yea I've tried to explain that to people before. People think without a fuse, without a breaker, the short protection of a BMS will save them...

Somehow software is going to save them from that type of failure? hahahahah

A BMS can save most of your stuff though, by dying before everything else does, which is what I'd expect. At least it's only a $80-$200 failure

I haven't seen anyone really thinking that here though, it's more random people on youtube / reddit that I've seen absolutely swear by the bms short circuit protection being enough

Maybe a brave soul with a surplus BMS could do a test also....

Real test would be several in series and see what goes first

My NH00 fuse holder is 135mm long. 160A fuse. Like class T, the fuses and holders get bigger depending on the rating of the fuse.I guess it depends on what hardware you use but for example Blue Sea holder is 178mm in total lenght

And NH1 fuse holder is 250mm long:

More extreme example: something like http://www.vte-europe.com/content/electromech/fuse/html/classt/classt.php

Up to 400A and only 45mm between centers on lug studs, whereas 400A rated NH2 fuse holder is 175mm between lug studs.

Since I fuse each battery and I run a 24v system 160A for each battery is plenty for me. My largest load will come via the 3kw inverter which limits me to about 125A. I can charge at up to 115A so well within the 160A fuse rating. My NH00 fuses and holders are a fraction of the cost of class T. Even if they were twice the size, I have plenty of room

I've seen the BMS work several times via other people. They end up with a hole through them where they melted.To a certain extent I believe the BMS will work. The inadequate (underrated) MEGA fuse is the secondary stop.

Maybe a brave soul with a surplus BMS could do a test also....

Real test would be several in series and see what goes first

Johan

Off-grid energy systems enthusiast.

Thanks everybody a lot for the input. Feature requests so far:

Update based on requests - let's start with the first one

Goal: Create a measurement setup for measuring the current versus time, including the maximum short circuit current and the fuse clearing time.

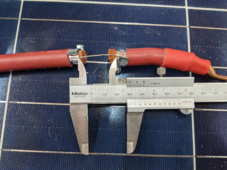

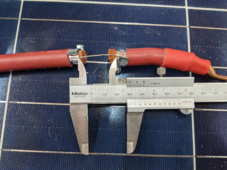

Test "fuse": 22 AWG | copper | 25mm length, see Figure 1.

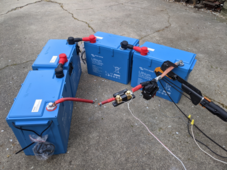

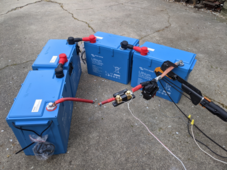

Experimental setup: Roughly the same as previously, but now expanded with data acquisition: Victron 500A SmartShunt (only using shunt part, not using the Victron measurement circuitry) → Arduino UNO → USB → laptop → Putty → *.txt → Excel. see Figure 2.

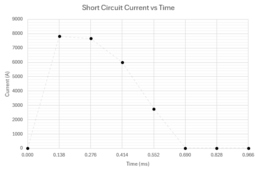

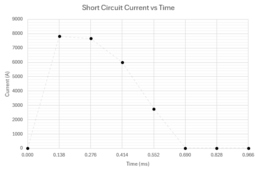

Result: The maximum current seems to be roughly 8kA* and the "fuse" clears in roughly half a millisecond as shown in Figure 4. The maximum sampling rate I could squeeze out of the Arduino so far is roughly 7 kHz. To see what happens within the first 0.138ms, faster hardware is required. Also there seemed to be random noise equivalent to 120A. The contactor did not weld closed this time (the same contacts were used as before, filed down a bit after breaking loose).

Conclusion: For data acquisition, the arduino works, but the sampling interval is close to the fuse clearing time. For a higher sampling rate, a better solution like an oscilloscope is probably preferred over the Arduino.

*Measurement accuracy estimation (for currents exceeding 7kA): Roughly 1%, based on Arduino's ATMEGA328P 10bit ADC specs of 2 LSB error . This assumes ADC reference voltage calibration, which was done just before (not during) the experiment.

Figure 1: Test "fuse".

Figure 2: Test setup.

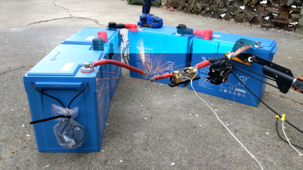

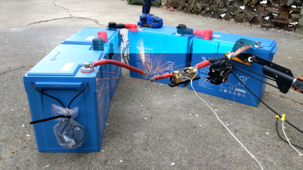

Figure 3: Fuse blows.

Figure 4: Short circuit current vs time.

- Create current versus time plot, e.g. using an oscilloscope / clamp meter with inrush (the latter has too low max current).

- Test more fuse types: Class T (example); bs88; NH; 300A MEGA; CNL; South Bend.

- Test breakers - cheap amazon etc. Install in wrong polarity too.

- Test 3D printed shields.

- Add BMS to circuit, e.g. with serverrack form factor battery, optionally in series with overcurrent device(s).

- Add inductor coil in circuit as soft start. How to best do this?

- Test 12V and 24V in addition of 48V.

- Fundraise and outsource to pros.

- Apply controlled constant current. Generate DC time-current "trip-curves" for a set of given constant currents.

- Add wire loop away from rest to cut, cut with better cutter, have disconnect bolt and blade style disconnect

Update based on requests - let's start with the first one

Goal: Create a measurement setup for measuring the current versus time, including the maximum short circuit current and the fuse clearing time.

Test "fuse": 22 AWG | copper | 25mm length, see Figure 1.

Experimental setup: Roughly the same as previously, but now expanded with data acquisition: Victron 500A SmartShunt (only using shunt part, not using the Victron measurement circuitry) → Arduino UNO → USB → laptop → Putty → *.txt → Excel. see Figure 2.

Result: The maximum current seems to be roughly 8kA* and the "fuse" clears in roughly half a millisecond as shown in Figure 4. The maximum sampling rate I could squeeze out of the Arduino so far is roughly 7 kHz. To see what happens within the first 0.138ms, faster hardware is required. Also there seemed to be random noise equivalent to 120A. The contactor did not weld closed this time (the same contacts were used as before, filed down a bit after breaking loose).

Conclusion: For data acquisition, the arduino works, but the sampling interval is close to the fuse clearing time. For a higher sampling rate, a better solution like an oscilloscope is probably preferred over the Arduino.

*Measurement accuracy estimation (for currents exceeding 7kA): Roughly 1%, based on Arduino's ATMEGA328P 10bit ADC specs of 2 LSB error . This assumes ADC reference voltage calibration, which was done just before (not during) the experiment.

Figure 1: Test "fuse".

Figure 2: Test setup.

Figure 3: Fuse blows.

Figure 4: Short circuit current vs time.

Last edited:

Pi Curio

Sunlicious

Would add one more - gPV 10x38 DC 32A Fuse with Din rail 32A fuse holder

- Test more fuse types: Class T (example); bs88; NH; 300A MEGA; CNL; South Bend.

The post I made was more of a call to the group for action and in no way a reference to your outstanding work and dedication. Just to clear that out.

- Fundraise and outsource to pros.

We spend hundreds on DC protection, without much, if any empirical data. Far cheaper for each to chip in something and have a real-world test done on the most popular DC protection in our systems.

Personally, I prefer seeing this done by talented individuals like you. You seem to understand most of the things involved in these tests.

For simple people like me, all I care about and mostly can comprehend is if the fuse can repeatedly open the circuit in a dead short, what amperage it managed to interrupt at what voltage and how fast was it(approximate Short circuit current vs time for reference).

Not to take any more of your time with my lengthy post, keep it short, and get down to business as they say;

Currently, I have an interest in 10x38 gPV fuse and din rail fuse holder.

If you would be interested in testing a DC gPV 10x38 32A fuse in a 32A 10x38 Fuse holder on a 48V battery, preferably 2 times, I would like to first sponsor the following parts for the test - Fuse and Fuse Holder, and then, in addition, a token of appreciation for your effort to your PayPal post-test result publication in here for everyone to see.

Thank you for sharing your work and enthusiasm with us. This type of content is well overdue and is invaluable to the DIY solar community.

robbob2112

Doing more research, mosty harmless

So, lemme get this straight, the fuse was given a massive over current and it blew with some firey results. It prevented an arc from forming. Pretty much what it was designed to do and if this was connected to wires and equipment it would have prevented the wires from melting. I can't recall how many times I have read here "fuses are to protect wires, not equipment", but it is a bunch.

A bit of molten metal flying strikes me as about as dangerous as when you flick solder off the tip of the iron. If you look at the fuse element through the plastic there isn't much metal there. Also I am pretty sure the fuse element is tin mixed with something. Would I want it on my bare skin? No!!! Do I think it would start a fire unless it did as someone mentioned and sparked the vent from a battery? Not likely.

I would would like to see other fuses tested with this method to see how they react.

Seems like it would be possible to build a test rig that is able to have a variable current output and increase across the rated current of the fuse. I am not that sort of engineer.

A bit of molten metal flying strikes me as about as dangerous as when you flick solder off the tip of the iron. If you look at the fuse element through the plastic there isn't much metal there. Also I am pretty sure the fuse element is tin mixed with something. Would I want it on my bare skin? No!!! Do I think it would start a fire unless it did as someone mentioned and sparked the vent from a battery? Not likely.

I would would like to see other fuses tested with this method to see how they react.

Seems like it would be possible to build a test rig that is able to have a variable current output and increase across the rated current of the fuse. I am not that sort of engineer.

heavily agree with both. Fuses are used all over electronics to protect electronics, not just wire.can't recall how many times I have read here "fuses are to protect wires, not equipment", but it is a bunch.

A bit of molten metal flying strikes me as about as dangerous as when you flick solder off the tip of the iron

Also yea maybe just try not to lay some dry hay & straw on your batteries and they won't catch fire with this :^)

my boxes are already concrete & metal though, pretty overboard and t class.. so probably even less of a reaction but we'll see. Definitely would like variable current output but dead short is good place to start

Johan

Off-grid energy systems enthusiast.

Today two more 22 AWG copper fuse wires were blown, similar to the previous black curve. The 22AWG copper wire fusing current is approx 41Adc (Preece), so this is a relatively small fuse having a clearing (blowing) time that is at the lower end of what I expect to be used in practise.

Goal: Evaluate if more data can be squeezed out of the little Arduino.

Result: Three times more data , resulting in >10 samples per (in this case relatively small duration) dead short events, see also the plot below. The sampling interval improved from 138 down to 45 microseconds. This went at the cost of resolution: The smallest measurable current increment is no longer 32A, but now approx 80A, which could be acceptable because the currents of interest are two orders bigger, i.e. 8000A. Note in the plot:

, resulting in >10 samples per (in this case relatively small duration) dead short events, see also the plot below. The sampling interval improved from 138 down to 45 microseconds. This went at the cost of resolution: The smallest measurable current increment is no longer 32A, but now approx 80A, which could be acceptable because the currents of interest are two orders bigger, i.e. 8000A. Note in the plot:

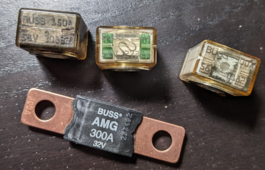

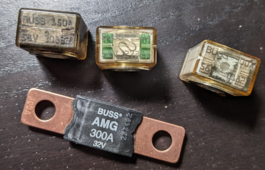

Next up: MRBF 30A, MRBF 300A, MEGA 300A. The 150A MRBF at the far left was the first one blown.

For special requests, we can talk using private messaging on this forum.

Goal: Evaluate if more data can be squeezed out of the little Arduino.

Result: Three times more data

- Orange curve: Again a ~25mm fuse wire length (just like the black curve from the previous experiment repeated here), but one battery terminal bolt was left loose at zero torque

. Still got the full 8kA current

. Still got the full 8kA current , yet zero damage at the loose stainless-bolt/lug/terminal

.

- Green curve: ~10mm fuse wire length (less than half the previous two), Torqued everything to spec again, reducing the circuit resistance.

Next up: MRBF 30A, MRBF 300A, MEGA 300A. The 150A MRBF at the far left was the first one blown.

For special requests, we can talk using private messaging on this forum.

Daddy Tanuki

Solar Wizard

I have spare class t fuses that are 80 amps I can send for testing if you need fuses

I wish I had more time. I have all the equipment to do these tests in my lab (I've done Class T and BS88 in the past for example).

As for the BMS (I tested the JK): in many cases and faults it will be much faster to react than the fuse, but it's not the only thing I would rely on. I size my fuses based on the max current it should see in normal operation. Inverters can fail and create a dead short, but if they normally only draw 100A, a 125A fuse will do even if the cable is rated for 200A or more.

The nice thing about Class T (and BS88) is that I have yet to see them throw molten metal/plastic around.

As for the BMS (I tested the JK): in many cases and faults it will be much faster to react than the fuse, but it's not the only thing I would rely on. I size my fuses based on the max current it should see in normal operation. Inverters can fail and create a dead short, but if they normally only draw 100A, a 125A fuse will do even if the cable is rated for 200A or more.

The nice thing about Class T (and BS88) is that I have yet to see them throw molten metal/plastic around.

I think the NH00 fuses are also designed to not throw molten metal around. Same principal of an enclosed ceramic fuse surround with silica sand.I wish I had more time. I have all the equipment to do these tests in my lab (I've done Class T and BS88 in the past for example).

As for the BMS (I tested the JK): in many cases and faults it will be much faster to react than the fuse, but it's not the only thing I would rely on. I size my fuses based on the max current it should see in normal operation. Inverters can fail and create a dead short, but if they normally only draw 100A, a 125A fuse will do even if the cable is rated for 200A or more.

The nice thing about Class T (and BS88) is that I have yet to see them throw molten metal/plastic around.

A very good alternative to class T and a lot cheaper in Europe. About $10 per fuse

on a dead short the BMS stopped it before the fuse triggered? that's damn impressiveI wish I had more time. I have all the equipment to do these tests in my lab (I've done Class T and BS88 in the past for example).

As for the BMS (I tested the JK): in many cases and faults it will be much faster to react than the fuse, but it's not the only thing I would rely on. I size my fuses based on the max current it should see in normal operation. Inverters can fail and create a dead short, but if they normally only draw 100A, a 125A fuse will do even if the cable is rated for 200A or more.

The nice thing about Class T (and BS88) is that I have yet to see them throw molten metal/plastic around.

OzSolar

Whatever you did, that's what you planned.

It really is. I've often theorized that a BMS sees the inverter's initial inrush as the beginning of a dead short thus goes into protection mode and shuts down.on a dead short the BMS stopped it before the fuse triggered? that's damn impressive

Brucey

Solar Wizard

If a BMS can trip from the surge of charging an inverters capacitors then a true short should be an easier thing to detect.It really is. I've often theorized that a BMS sees the inverter's initial inrush as the beginning of a dead short thus goes into protection mode and shuts down.

on a dead short the BMS stopped it before the fuse triggered? that's damn impressive

Yep!

yea. I've seen them blow up too. I guess it depends on what the chip is busy doing. I assume the decision to react is all on the main micro controller cpu and not some dedicated oneIt really is. I've often theorized that a BMS sees the inverter's initial inrush as the beginning of a dead short thus goes into protection mode and shuts down.

If you're constantly monitoring it though you do get a head start on when you react as you say. The speeds of these electrical shorts are as fast as the electricity in a cpu though.. so the latency in a processor is higher, so it's a gamble imo

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,792

Fuses, breakers, relays are milliseconds. FETs switch at 10 or 100 kHz in power supplies.

Maybe a BMS with contactor wouldn't be fast enough. Might be enough to protect itself and wires, but possibly a fast fuse in series would get blown first (that is its job.)

I never trust microprocessor for real time. Mainly because I never trusted the programmers on the same project, but not entirely.

My hardware had analog circuitry to detect and shut down (filament or amplifier protection). Easy enough to do for the BMS, voltage across shunt into a comparator, drives a FET to discharge gate of power FETs. Only question is how fast you can get it below threshold voltage.

I would do similar for cell over-voltage, although that could be handled with polling. Maybe a state machine or dedicated uP.

Maybe a BMS with contactor wouldn't be fast enough. Might be enough to protect itself and wires, but possibly a fast fuse in series would get blown first (that is its job.)

I never trust microprocessor for real time. Mainly because I never trusted the programmers on the same project, but not entirely.

My hardware had analog circuitry to detect and shut down (filament or amplifier protection). Easy enough to do for the BMS, voltage across shunt into a comparator, drives a FET to discharge gate of power FETs. Only question is how fast you can get it below threshold voltage.

I would do similar for cell over-voltage, although that could be handled with polling. Maybe a state machine or dedicated uP.

Even if the programmers don't mess it up, it's be pretty sad if you got a https://en.wikipedia.org/wiki/Soft_error from space cosmic rays when you could have had a breaker and or fuse there

Similar threads

- Replies

- 7

- Views

- 490

- Replies

- 2

- Views

- 138

- Replies

- 4

- Views

- 303

- Replies

- 11

- Views

- 516