Hi,

I would like to take this opportunity to warn all consumers and companies considering purchasing EVE LF280K Grade-A cells with the new type of terminal.

The reason is that EVE has not adapted the packaging in which the battery cells are shipped.

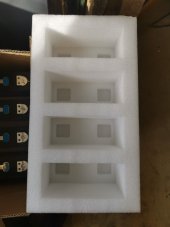

As you can see in the pictures, the terminal is the highest non-flexible point. On top of the terminals there is then an 8mm polyfoam for protection and then the box is closed. Any force on the top of the box will be distributed to the cell terminals.

When ordering a full sea pallet, 144pcs LF280K cells, several cartons are stacked on top of each other. When the carton absorbs moisture during the sea transport, strength is lost, and with the small margin that exists in the height, the weight of the stacked cartons ends up on the terminals of the cells.

The terminals are subjected to stress, and the Grade-A cells you bought are now Grade-D cells or should possibly be discarded immediately.

I think it is unbelievably bad that the cells are packaged in a way where the weight from cartons above ends up on the terminals.

We have an order placed 1 month ago directly with EVE for 144pcs LF280K cells. These will be shipped in the coming days. EVE's official sales representative is of the opinion that we should have specified when ordering if we wanted them better packaged. And if there has been stress on the terminals during shipping, which might lead to malfunction of the battery packs in our product, "it will be covered by thier 1 year warranty". Well, that will not help us.

As we refuse the cells being shipped like this, they have now offered to put the cartons in wooden boxes if we pay extra. However, uncertain if this can be resolved as the sea pallet has already been shipped to the CIF agent.

Images below are from a shipment we received a week ago, all the terminals are bent due to force from above. These are EVE LF280K cells bought via a distributor in EU, which claim to also buy directly from EVE. I have sent these images to EVE which has confirmed that the 144pcs cells in our order are packaged the same way.

I'm kinda upset that one of the biggest LFP manufacturers in China act like a random scam guy on alibaba, and has such poor packaging that the integrity of the cells can't be garanteed upon arrival.

I would like to take this opportunity to warn all consumers and companies considering purchasing EVE LF280K Grade-A cells with the new type of terminal.

The reason is that EVE has not adapted the packaging in which the battery cells are shipped.

As you can see in the pictures, the terminal is the highest non-flexible point. On top of the terminals there is then an 8mm polyfoam for protection and then the box is closed. Any force on the top of the box will be distributed to the cell terminals.

When ordering a full sea pallet, 144pcs LF280K cells, several cartons are stacked on top of each other. When the carton absorbs moisture during the sea transport, strength is lost, and with the small margin that exists in the height, the weight of the stacked cartons ends up on the terminals of the cells.

The terminals are subjected to stress, and the Grade-A cells you bought are now Grade-D cells or should possibly be discarded immediately.

I think it is unbelievably bad that the cells are packaged in a way where the weight from cartons above ends up on the terminals.

We have an order placed 1 month ago directly with EVE for 144pcs LF280K cells. These will be shipped in the coming days. EVE's official sales representative is of the opinion that we should have specified when ordering if we wanted them better packaged. And if there has been stress on the terminals during shipping, which might lead to malfunction of the battery packs in our product, "it will be covered by thier 1 year warranty". Well, that will not help us.

As we refuse the cells being shipped like this, they have now offered to put the cartons in wooden boxes if we pay extra. However, uncertain if this can be resolved as the sea pallet has already been shipped to the CIF agent.

Images below are from a shipment we received a week ago, all the terminals are bent due to force from above. These are EVE LF280K cells bought via a distributor in EU, which claim to also buy directly from EVE. I have sent these images to EVE which has confirmed that the 144pcs cells in our order are packaged the same way.

I'm kinda upset that one of the biggest LFP manufacturers in China act like a random scam guy on alibaba, and has such poor packaging that the integrity of the cells can't be garanteed upon arrival.

Last edited: