I've only seen spacers provided by resellers, never by cell manufacturers. But I can not prove a negative. Please show us where you've seen this.

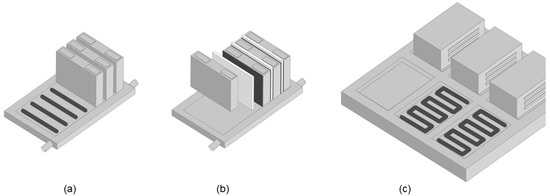

Just start shopping for aluminum shell cells and you'll see a bunch of variations on the spacer theme today. You can shop domestically on ECPC or on alibaba. You can read a long thread about this where we just re-hashed all this same stuff on cruiser forum. Or, you can watch Will's video of the "Fortune" cells and witness some spacers in action.

The distinction between reseller and manufacturer is less clear than your earlier statements lay out. My manufacturer has several discrete facilities and warehouses the cells in Shenzhen. They have "inside reps" who sell exclusively their product, but they also work with a variety of resellers/brokers. And, of course, some domestic shops import their cells and relabel/mark them up.

I worked directly with the exclusive rep in SZ when I ordered my cells.

If your cells move around enough, relative to each other, to chafe the (very thin) plastic cover, I would say you've failed in securing the cells. They should be secure enough to not move. Not because of chafe, but to not put physical strain on the terminals.

I definitely agree that avoiding putting any mechanical load on the terminals is very important.

I do not agree that I am willing to trust the thin plastic. Even in installation it could be nicked or scraped, and I would have little way to tell until one of my cells starts interacting with its neighbor in some undesirable way, maybe slowly over years. Again: most manufacturers want us to insulate the cells in some way.

To clarify, it was a 3P16S pack. The temp sensors were permanently mounted, thermally connected to the terminals, should be the hottest part of the exterior of a plastic cell.

I really think plastic cells are irrelevant here. They have an inferior density, clearly inferior thermal shedding properties, and they are the "version 1" of LFP. I'm not saying they don't make great batteries -- but I'm also not surprised you don't see much thermal action on the outside of them.

You need to show where you find your "pre-spaced" cells.

I don't

need to do anything, but I've tried to present ample evidence above, in the two minutes I'll grant you to write this reply. You should go brush up on the modern offerings. Seriously, send a note to a couple reps and ask them about the insulators. We've already done it, and we already know what they say.