Any idea if the "turn BMS ON"-button connects two pins somewhere?

As soon as I have it I'll open it up and compare with an older one.

Any idea if the "turn BMS ON"-button connects two pins somewhere?

That is where I am now. I am building a 2PS4 and a 3P4S and have heard that they will have a 4S JK in a month or so.I was disappointed with my batch because I ordered mine just before they updated the design to enable the LCD Screen. Mine have the RS485 & CanBus ports and Bluetooth of course. Had I known to wait 2 weeks or so I would have.

Thanks for the great writeup.

I cannot find it now but on the a description that I found on the display, it said (if memory is correct) that you could turn the BMS off by "long pressing" the button. I cannot remember the time but I have several other devises that turn off with a 3-5 second press and hold on the button.

wonderful write up!Ok, update time. Finally had some time to have a look at the new BMS.

View attachment 81464

The new one on the right, old one on the left. They're both 100A versions to keep the comparison easier. The port to the right of the GPS/RS485 label is the display port. As Dave Jones would say: "Don't turn it on. Take it apart!"

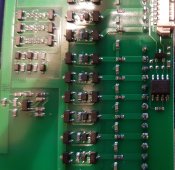

View attachment 81465

New one on the right again. The original is hardware version 6.0, the new one 8.0. There have been a few changes, mostly on the other side of the board. The main change on this side of the board is the micro controller. The old version had an original STM32F103; probably due to shortages or because more resources were needed, it is replaced with a GD32F103. This is a pin compatible clone of the STM, it's used on some Bluepill boards and finds its way into many products these days since it's cheaper and actually available, unlike the STM. It also has more RAM/FLASH and can run at higher clock speeds. I'm actually surprised they didn't have the GD32 on there from the beginning. The MOSFETs are still the same: G042N10.

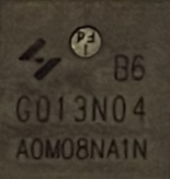

View attachment 81466

The GD32.

View attachment 81467

Other side of the board. More profound changes here. For one, the Bluetooth module was changed. Didn't look at the details, but they're both common modules. The chip at the bottom is a YD3082, which is an RS485 transceiver, which is what is driving the display. I'm not sure yet if this shares the same RS485 bus where one connects the RS485 dongle to. I'll find out later. There are also some added digital isolators that weren't there before (an 122U31) - probably to provide better isolation between the power and control side.

View attachment 81469

The YD3082 RS485 transceiver in the middle to the right.

This is the Display itself. It's very clear and bright, and the power button on the side works fine to turn the BMS on. I somehow wish it could be used to turn the BMS off again, but that's not a deal breaker. Ignore the 6.6V and state of charge, I just connected the BMS to two spare cells and a power supply.

View attachment 81470

I originally wanted to create a custom enclosure for it, but the handle bar mount can be removed easily, and it looks much better this way.

View attachment 81471

Of course, I also opened the display:

View attachment 81472

It's based around a Holtec HT1621 display driver on the right. This thing has a serial interface, and the other chip to the left is a hk32f030, another microcontroller that takes the incoming data and talks to the Holtec chip.

View attachment 81474

The LCD display itself.

I want to dig in deeper in some of the changes and other aspects of the BMS. For one, I really want to figure out how the power button is implemented, and if this is a software or hardware thing (or both). I don't know when I will have time for this though; now that I have one sitting on my desk I want to get back to the RS485 communication, finishing my Grafana interface and then go to the next step: implement a supervisor which has a full overview of all components and their status, and can make decisions based on this...

Vdss 100V rating!

Yes, here too:

JBD/Overkill vs JK/Heltec BMS

Has anyone done a comparison between the JBD and JK BMS's? They look very similar to me. The JBD seems to use the Xioxiang app, and the JK uses thr ENJpower app. The apps are also VERY similar. I know Overkill is JBD, ans Heltec is JK based. Is the same manufacturer making both? I am not as...diysolarforum.com

This one above had the G035N10N - also 100V, but higher max current.

I look at your RS-485 code and my poor brain starts to smoke. I have not needed to do any real programing since collage and that was in Fortran with punch cards.I've updated my repo to read the data from the BMS for Grafana display.

GitHub - PurpleAlien/jk-bms_grafana: Read data from a JK BMS and graph it in Grafana

Read data from a JK BMS and graph it in Grafana. Contribute to PurpleAlien/jk-bms_grafana development by creating an account on GitHub.github.com

NMEA 2000 (I mostly know it as IEC 61162-3) is essentially plug an play. However, to do that, there is a whole lot of higher level functionality on top of the physical CAN bus and protocol. That RS485 code you see on my github is essentially something that lives right above the hardware, where we take incoming data bytes and decode those bytes according to a protocol description of what byte means what, in what order, how many need to be grouped, etc.

That said, you don't have to connect an inverter to the BMS. They work fine independently. But yes, if you want the BMS to control the inverter, etc. there is more involved unless you go with specific hardware that supports this (like Batrium BMS with Victron hardware).