Anyone still getting after it with this battery research? I came to the same conclusion as

@danielfp248 that Zn Br cells are not a viable or safe homemade solution. Zn I2 is a logical next step. Here are some other ideas to consider:

1) Zinc Iodine: Use of propylene carbonate as complexing agent (

https://www.sciencedirect.com/science/article/abs/pii/S0013468619312939?via=ihub)

2) Zinc Iodine: Use of Ammonium Chloride as electrolyte enhancer (

https://www.sciencedirect.com/science/article/abs/pii/S2405829720302531?via=ihub)

There seem to be some irreversible reactions related to the ZnI2 battery on the iodine side, especially if the battery is over charged, so keep that in mind.

Zinc Nickel

I went down the rabbit hole with Zinc Nickel batteries, and I can tell you that getting an electrochemically active version of Nickel Hydroxide - Ni(OH)2 is an extremely finicky process involving PH / temperature / proper precursor matching / mix rate / drip rate.... I got it done once! and could not repeat the process. Nickel compounds are also expensive and I've put this one on the shelf

Zinc Mn3O4

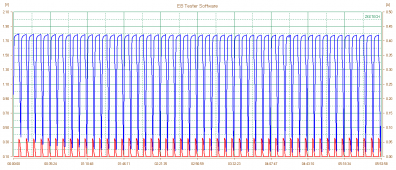

I've moved on to testing Zinc Manganese based chemistries. I am keeping with the Zinc anode theme because it's cheap, available, offers great voltages and well studied (even with potential dendrite issues). Manganese is also very cheap ( Just look at the price of a 5lb back of MnSO4 on amazon... and compare that to a 5lb bag of NiSO4)

This is a good overview to help guide research:

https://onlinelibrary.wiley.com/doi/10.1002/inf2.12042

Best of luck! and I definately understand what

@Juptron is saying about keeping his own research protected. I've also encountered similar problems in the literature, especially with chinese type papers, and I think there are plenty of mistakes in a tremendous amount of battery related articles (both accidental and possibly deliberate...)

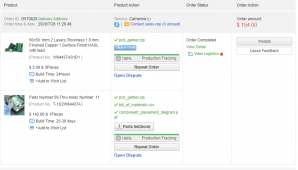

I've attached some files. Spending money on all these articles is expensive, maybe we can share the load here a little bit

hopefully I start a trend.