Sandwich a solid plate of polymer under the bolt head. It wouldn't need to be very thick to provide absolute isolation.I was thinking of counterboring so I could put a bolt through from the backside to work like a stud. Then the bolt wouldn't touch anything except the basbar and the lugs.

But is would get tightened down pretty tight so whatever I use can't smash or crack easily. I could put a washer on the backside too.

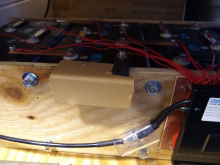

I would just use T-Nuts like these.