You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EVE battery terminal repair

- Thread starter davidnordstrom

- Start date

hwy17

Anti-Solar Enthusiast

Oh no. Unfortunately no there are not known good ways to do that.

Drilling and tapping to bolt it down would be the only possibility, but the terminals are very shallow.

Drilling and tapping to bolt it down would be the only possibility, but the terminals are very shallow.

davidnordstrom

New Member

Yes, if only it was known how deep and wide one could go!Oh no. Unfortunately no there are not known good ways to do that.

Drilling and tapping to bolt it down would be the only possibility, but the terminals are very shallow.

Do you think welding could be an option? That assumes the current is thought to go through were it is currently welded, if you know what I mean? I'm guessing it is now required to hold any significant force downwards to create a connection there?

hwy17

Anti-Solar Enthusiast

It has always been assumed that only a laser welder can do it fast enough to avoid heating the terminal too hot. Eve has a spec for how hot it can get.Do you think welding could be an option? That assumes the current is thought to go through were it is currently welded, if you know what I mean?

hwy17

Anti-Solar Enthusiast

The 304 spec sheet from EVE may also specify the depth of the terminal. I think the welded center you have still stuck on the terminal would help to add depth.

davidnordstrom

New Member

OK, and you can't just do it in small steps and let it cool in between?It has always been assumed that only a laser welder can do it fast enough to avoid heating the terminal too hot. Eve has a spec for how hot it can get.

hwy17

Anti-Solar Enthusiast

Community has always thought no but if you have aluminum welding ability it would be cool to have someone try.OK, and you can't just do it in small steps and let it cool in between?

I don't know aluminum welding, maybe the terminal would have to get too hot to get any pool going at all, if that's how it works. Aluminum is an effective heat conductor so it's going to be sucking the heat out of the weld fast.

Partimewages

Solar Addict

Find a local aluminum laser welding service. Just an idea

davidnordstrom

New Member

I noticed it was loose as I was tightening it. Didn't notice a crack or anyting... guessing it was defective from factory but I first noticed it now. Used a torgue set at 6nm, but I never got to the click before noticing.You did that at 6nm? Or were you really hauling in it?

davidnordstrom

New Member

I bought them from eelbattery.com. They were quick to respond before, but on this issue I have not yet recived a reply. Maybe it should be a warranty issue, what do you think?Where did you order the cells?

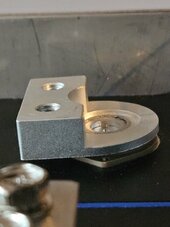

Can you take a detailed picture of a terminal without anything connected?

Curious if you have threaded inserts in those.

Attachments

Those also don’t like like true Eve spec terminals with threaded inserts.

As for root cause I agree with Davis, weight on the terminal weakened it and you were the last straw.

I’d inspect the other cells for how flat those terminals are.

As for root cause I agree with Davis, weight on the terminal weakened it and you were the last straw.

I’d inspect the other cells for how flat those terminals are.

zgk51

New Member

This is a worry.

I'm waiting delivery of some used cells myself where some might have this problem... I briefly considering tig welding them myself but the thing with aluminium welding is everything gets super hot because of it's high conductivity. Steel is possible to do a quick pulse and keep it localised but for aluminium this is not possible. So laser welding would be the only way.

You could drill and tap? Or perhaps drill a shallow hole and then use some sort of self-tapping tapered fastener similar to a wood screw. Perhaps a BRASS screw? (assuming brass had higher conductivity than steel.... I'd have to look that up) or an aluminium screw? if you could source or machine one.

I'm waiting delivery of some used cells myself where some might have this problem... I briefly considering tig welding them myself but the thing with aluminium welding is everything gets super hot because of it's high conductivity. Steel is possible to do a quick pulse and keep it localised but for aluminium this is not possible. So laser welding would be the only way.

You could drill and tap? Or perhaps drill a shallow hole and then use some sort of self-tapping tapered fastener similar to a wood screw. Perhaps a BRASS screw? (assuming brass had higher conductivity than steel.... I'd have to look that up) or an aluminium screw? if you could source or machine one.

Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

Screw Hole Depth is 6mm to point.

You can drill it out with a 1/4" HSS bit with a depth stop so you don't go too far (you have a small grace with these terminals because they do not go into the physical cell). So do it slowly and cautiously as it is soft aluminum.

Use a M6 Helicoil Kit & Rethread with that & insert the helicoil and voila.

Example: https://www.amazon.ca/Helicoil-5546-6-Metric-Coarse-Thread/dp/B0002KKPXK

Remember, you don't need to over torque and strip the threads and BE CAREFUL not to Cross Thread !

You can drill it out with a 1/4" HSS bit with a depth stop so you don't go too far (you have a small grace with these terminals because they do not go into the physical cell). So do it slowly and cautiously as it is soft aluminum.

Use a M6 Helicoil Kit & Rethread with that & insert the helicoil and voila.

Example: https://www.amazon.ca/Helicoil-5546-6-Metric-Coarse-Thread/dp/B0002KKPXK

Remember, you don't need to over torque and strip the threads and BE CAREFUL not to Cross Thread !

Similar threads

- Replies

- 88

- Views

- 7K

- Replies

- 29

- Views

- 1K

- Replies

- 154

- Views

- 13K

- Replies

- 79

- Views

- 7K

- Replies

- 33

- Views

- 2K