Colonel.lp

New Member

- Joined

- Jun 8, 2020

- Messages

- 135

My 4 cells arrived today from Xuba, the packaging was fine, but one of the cells has a dent near the top, about 8mm across and 1.5mm deep.(1st picture) What do people think about this in terms of long term functioning of the cell? Should I be adamant about a replacement?

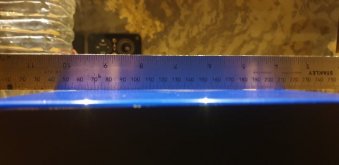

Also is it normal that the sides of the cells undulate, I've never had cells this large before, so was expecting perfectly flat. Across the large sides there is a slight wave(3rd picture), and top to bottom of the large sides they all scallop before the top(2nd picture)

I'd like to know what's what before I chat to Amy.

Also is it normal that the sides of the cells undulate, I've never had cells this large before, so was expecting perfectly flat. Across the large sides there is a slight wave(3rd picture), and top to bottom of the large sides they all scallop before the top(2nd picture)

I'd like to know what's what before I chat to Amy.